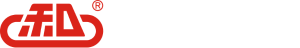

Performance

High capacity and low energy consumption

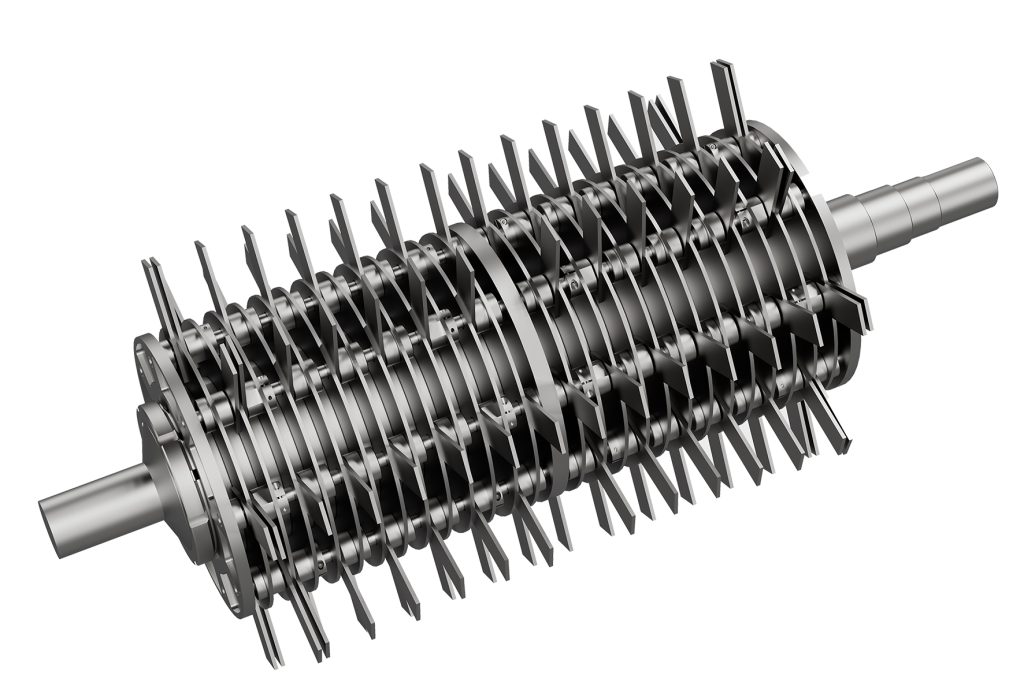

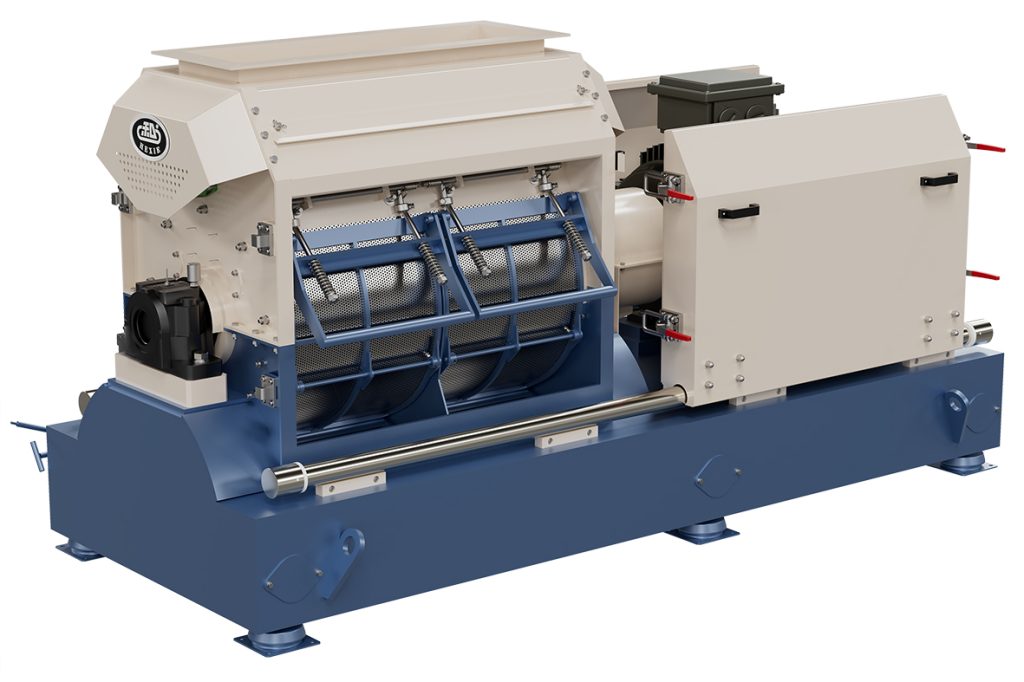

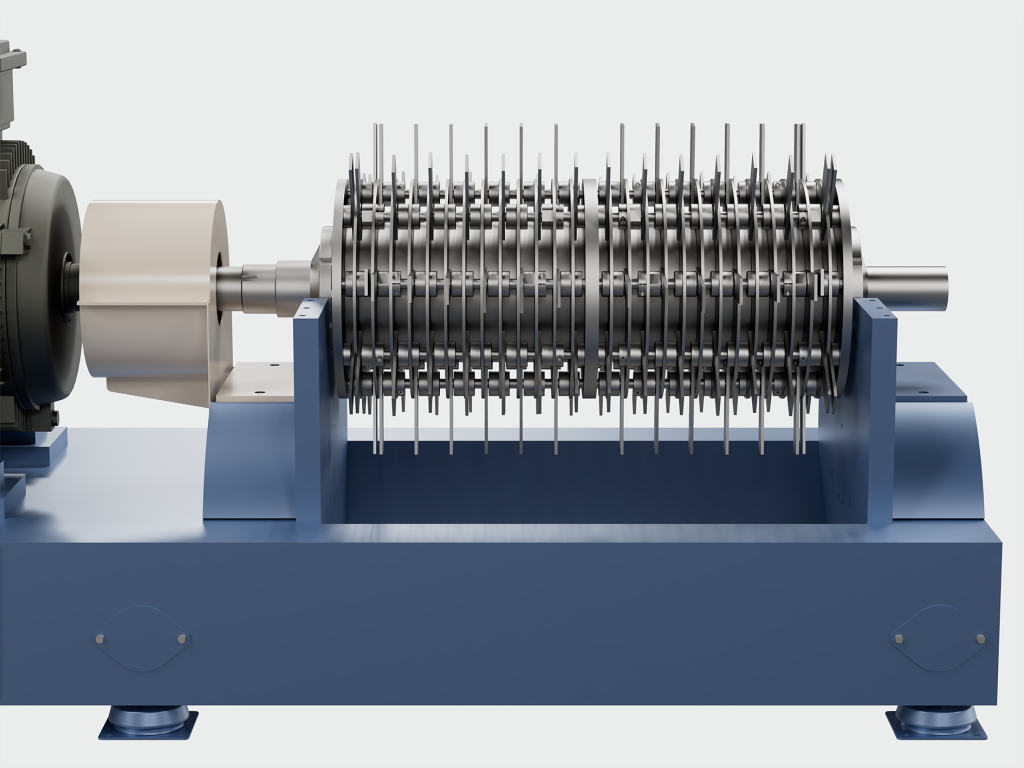

- 1. Optimize the rotor structure, large diameter rotor effectively adjust the direction of air flow in the crushing room, so that the material is in the effective crushing zone, forget the output, reduce energy consumption, grinding at the beginning of acceleration is equipped with wear-resistant tooth plate, the bottom of the U-shaped second strike groove, so that the material punching more thoroughly.

- 2. Staggered arrangement of the hammer, increase the effective screening area, make the hammer wear uniform, prolong the life of the hammer.

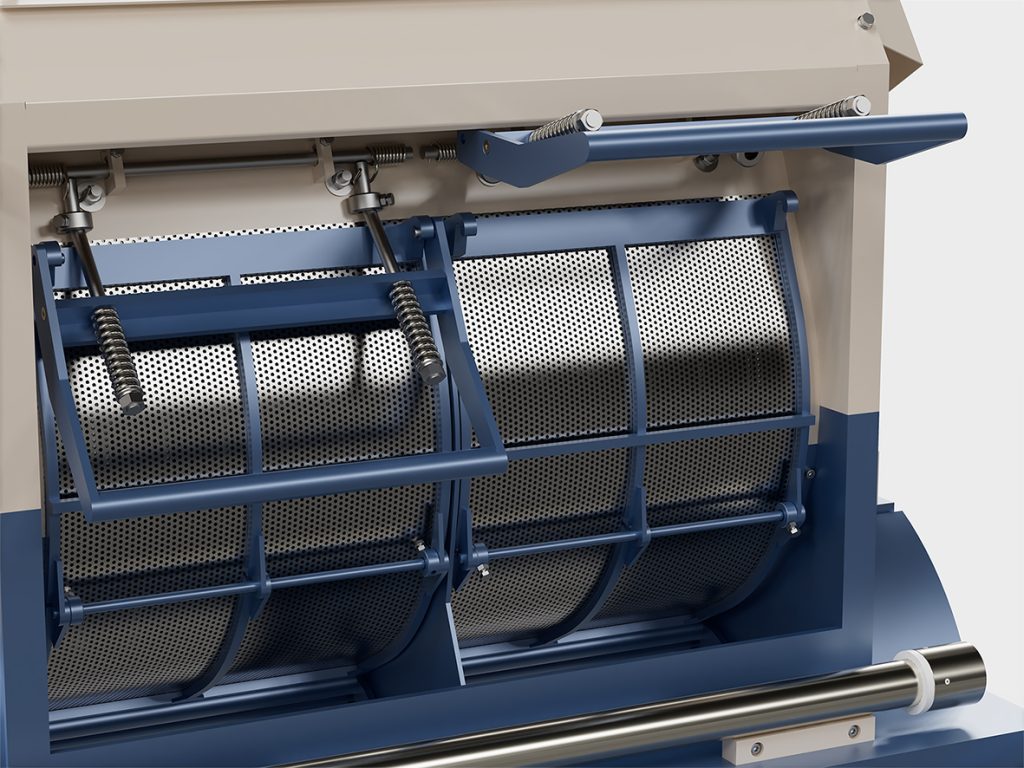

- 3. Multi-chamber crushing chamber can reduce screen loss, flexible adjustment of particle size.

- 4. Encryption hammer design, suitable for coarse and fine grinding of raw materials, grinding particle size uniform, micro-grinding performance to a new high.

Ultra-stable and durable

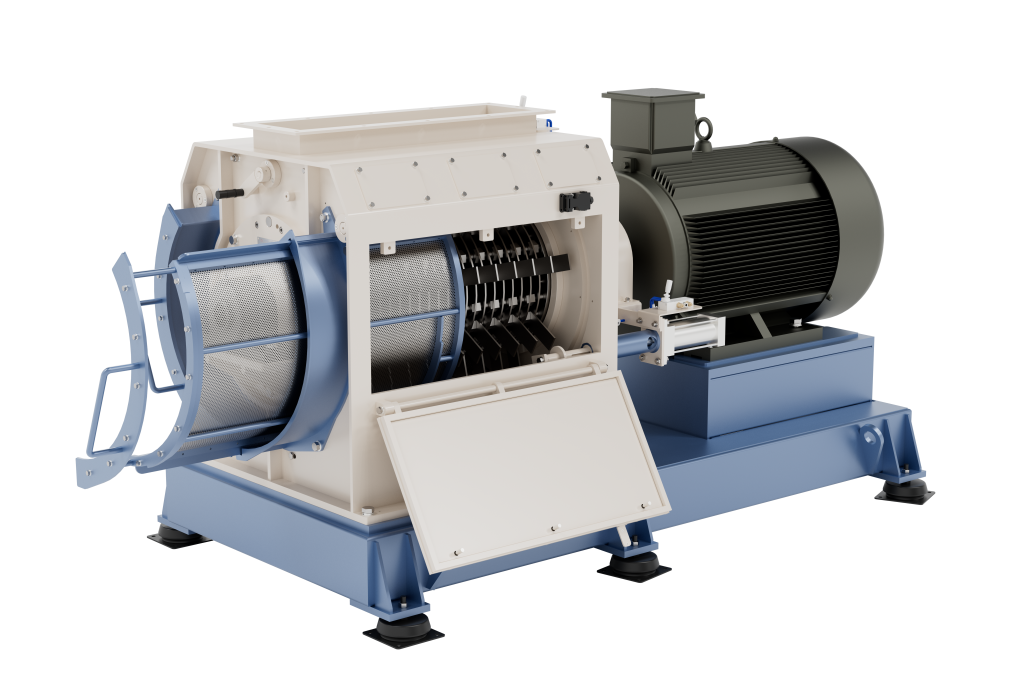

- 1. The overall finishing milling base has small vibration, stable operation, and the coin can be in an upright state under working condition.

- 2. High precision dynamic balance detection rotor, equipment vibration is small, low noise,

- 3. The hammer is made of special alloy steel and hardened by suspended tungsten carbide surface to achieve higher strength and durability.

- 4. Test machine by machine, running time > 45min, stability is better than the national standard, vibration speed up to 2-4mm/s (national standard ≤16mm/s).

- 5. The new snake-like spring coupling (plum coupling) has good damping performance, large variable load bearing capacity, large displacement compensation space, reliable operation, and effectively avoid bearing heating phenomenon.

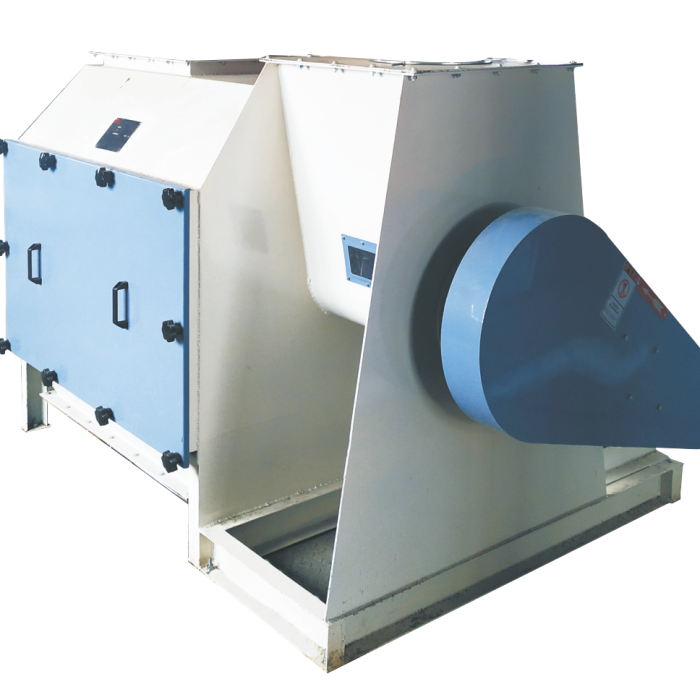

Easy to operate

- 1. Movable operation door, convenient maintenance.

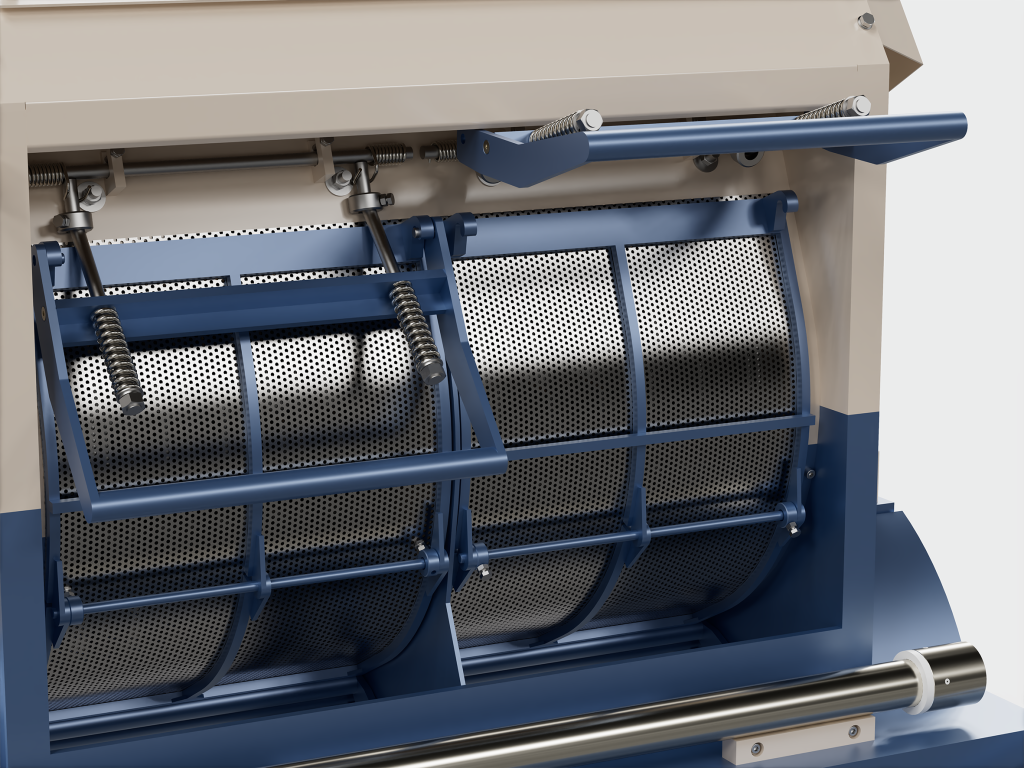

- 2. Multi-stage linkage press screen mechanism makes it more convenient to change the screen.

- 3. Optimized pin shaft and pin sleeve structure, more convenient replacement of hammer.

- 4. A full range of linkage control system, always protect the safe operation of equipment.

- 5. Technical description, product model, main engine power, feeding power, rotor diameter, number of hammer,capacity.

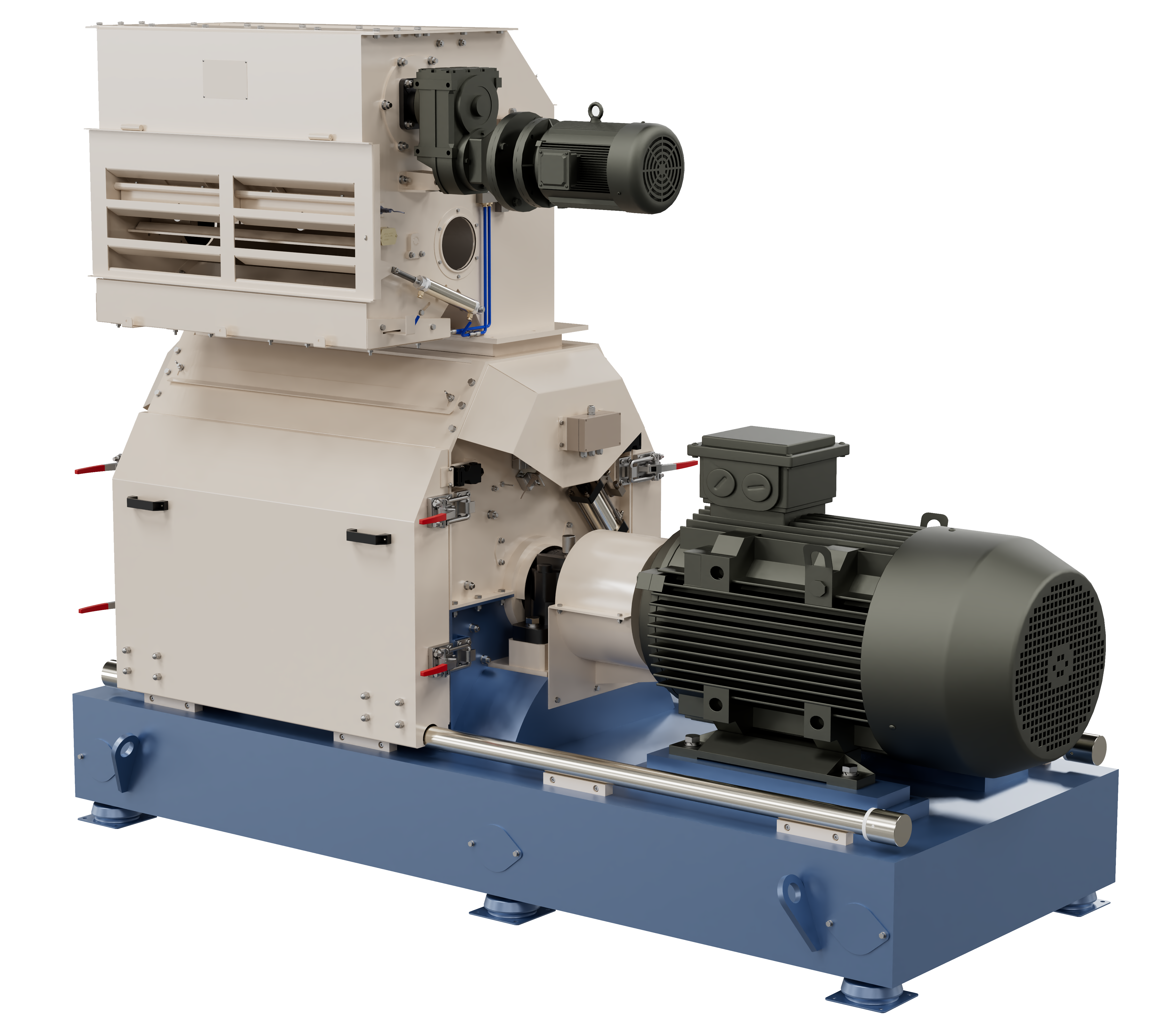

Application

SFSP series drop-shaped hammer mill can be used for fine grinding in pet food and fish feed processing, and can also be used for coarse grinding in compound feed, flour processing and biomass processing.

Specification

| Model | Rotor Diameter(mm) | Grinding chamber width(mm) | Main Power(kw) | Capacity(t/h) |

| SFSP-66×60A | 660 | 600 | 55-75 | 7-12 |

| SFSP-66×80A | 660 | 800 | 90-110 | 12-15 |

| SFSP-66×100B | 660 | 1000 | 110-160 | 15-27 |

| SFSP-66×150 | 660 | 1500 | 200-315 | 35-52 |

| SFSP-63×35 | 630 | 350 | 22-30 | 1-5 |

| SFSP-63×45 | 630 | 450 | 37-45 | 1.4-7 |