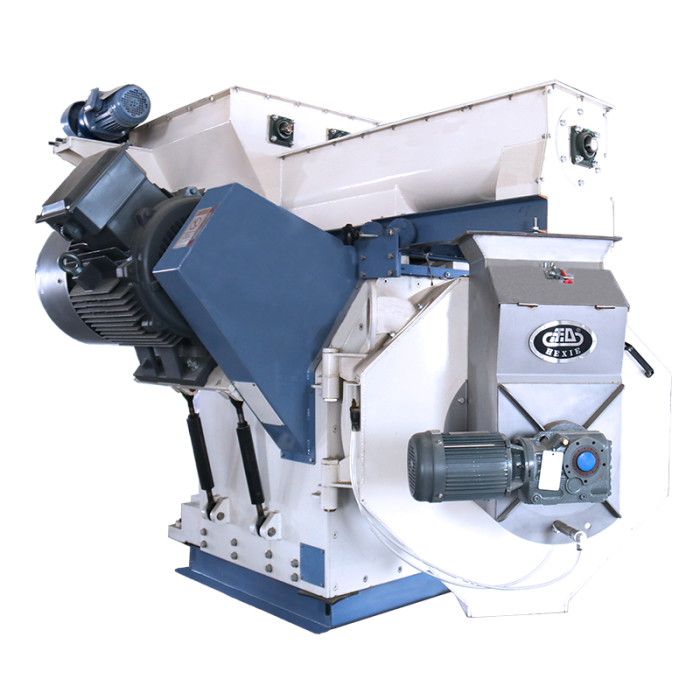

Product Performance

HHDJ series single-shaft paddle mixer

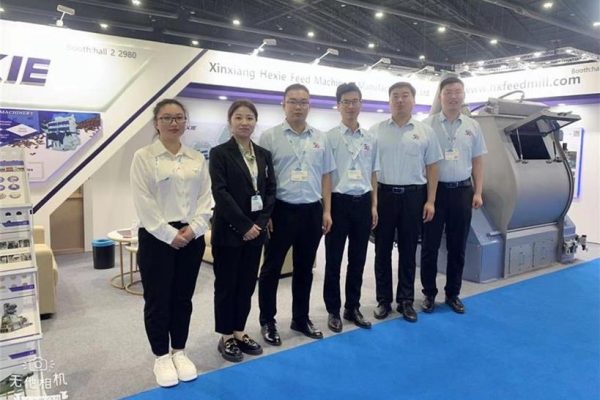

HEXHI's high-precision mixing technology has been available since 1992 and has been continuously improved to meet modern standards. Mixers with innovative technology are so efficient and precise that they raise the standard requirements for mixing in powders, food, feed and industry, proving that they are able to meet higher requirements than other existing mixers. Today, Hexie has delivered tens of thousands of mixing equipment to all over the world, and continues to improve and optimize the details of the equipment in order to provide our customers with reliable, accurate and attractive products.

Hexie HHLJ Series Ribbon Paddle Mixer is a batch mixer suitable for very precise mixing of almost any type of powdered or granular raw materials. The mixer rotor adopts Hexie's patented spiral blade structure, which can complete high-precision mixing within 3-5 minutes.

Excellent mixing quality in less time

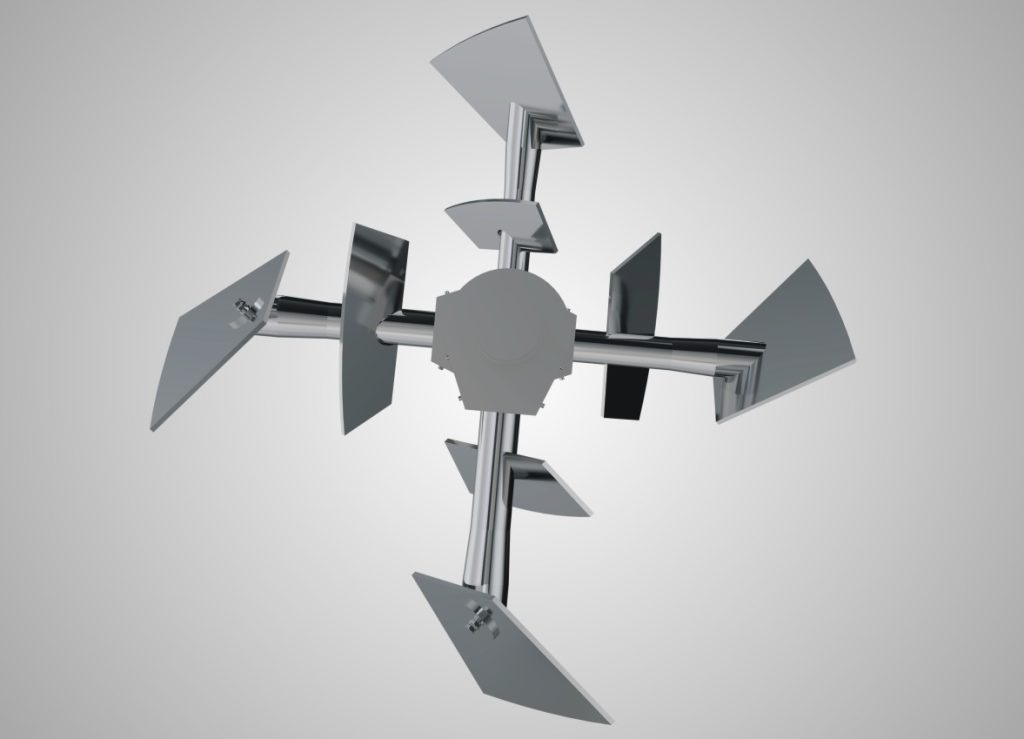

Short mixing time, high efficiency and no material leakage are the keys to obtain high-quality feed. This is what the HHDJ series offers. The unique dual rotating mixer design ensures minimal material accumulation. With complete discharge through a pneumatic large outlet discharge door with locking device, HHDJ provides a high quality product.

Performance Characteristics

1. Inner and outer double-layer blade design, special arrangement structure, high mixing uniformity, short mixing cycle; Mixing time 1-3min, coefficient of variation CV≤5%; Materials with large physical property differences such as specific gravity, particle size and shape are not easy to produce segregation when mixing.2. Equipped with liquid adding system, can add a variety of liquids (water, grease, molasses, etc.).

2. Equipped with liquid adding system, can add a variety of liquids (water, grease, molasses, etc.).

3. The variable range of filling coefficient is large, from 25% to 100%.

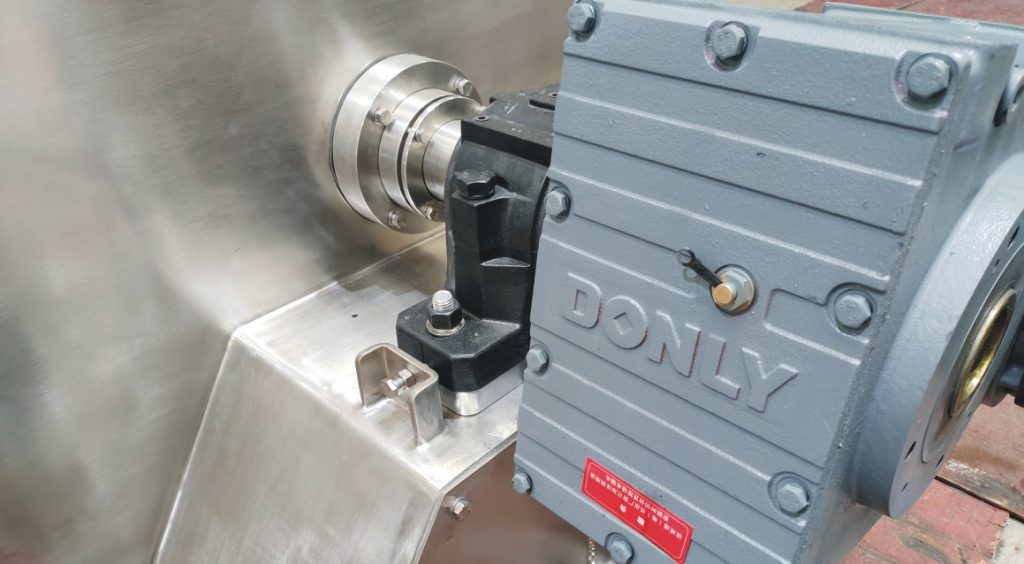

4. Adopt hard tooth surface reducer and rotor direct transmission; Stable and reliable transmission, long service life, very low maintenance cost.

5. Adopt full-length large door discharging structure, fast discharging, ensure low residue, prevent cross contamination.

6. Equipped with safety interlock, protect personal safety.

7. Carbon steel or stainless steel can be selected according to different uses.

8. Suitable for feed additives, chemical, pharmaceutical, pesticide, dye and food industries.

9. Technical description, product model, power, effective volume, batch mixing amount, mixing time, coefficient of variation.

Application

Technical Description

| Product Model | Power(kw) | Effective Volume (m³) | Capacity(kg/batch) | Mixing Time(min) | Coefficient of Variation (cv) |

| HHDJ-0.5 | 5.5 | 0.5 | 250 | 1-3 | ≤5% |

| HHDJ-1.0 | 15 | 1.0 | 500 | ||

| HHDJ-2.0 | 22 | 2.0 | 1000 | ||

| HHDJ-4.0 | 37 | 4.0 | 2000 | ||

| HHDJ-6.0 | 45/55 | 6.0 | 3000 | ||

| HHDJ-8.0 | 2×37 | 8.0 | 4000 | ||

| HHDJ-10.0 | 2×45 | 10.0 | 5000 |