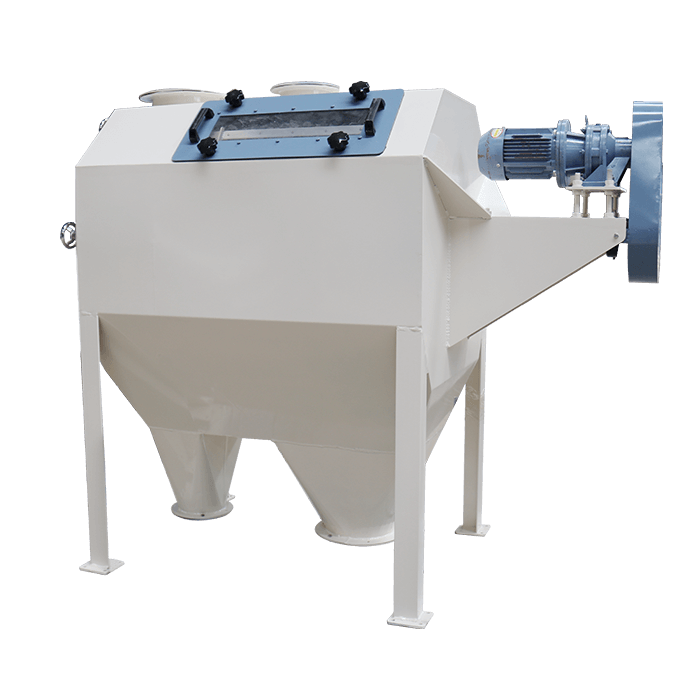

Performance

- 1. With the patented rotor structure of "screw + paddle", no mixing dead corner, high mixing uniformity;

- 2. Use the hard gear surface reducer and mixer rotor direct connection transmission;

- 3. Simple structure, compact, installation space is small, smooth transmission, high efficiency, better reliability, long service life, maintenance cost is very low;

- 4. The machine is equipped with liquid adding pipeline, suitable for adding water, bacterial liquid, oil, molasses and other liquids;

- 5. The shaft end and discharge door adopt unique mature sealing technology to ensure no leakage;

- 6. Increase the power configuration, suitable for mixing material with 50% moisture content;

- 7. Supports customization of contact material parts made of 304 stainless steel;

- 8. Suitable for biological fermentation feed, biological organic fertilizer, chemical industry, medicine, pesticide, dye and food and other industries.

Technical Description

| Product Model | Power(kw) | Effective Volume(m³) | Batch mixing capacity(kg/p) | Mixing Time(min) | coefficient of variation |

| HHLJ-2.0 | 15 | 2.0 | 1000 | 3-5 | ≤5% |

| HHLJ-4.0 | 30 | 4.0 | 2000 | ||

| Note: The moisture content of the batch moisture content material is <16%, calculated based on the material bulk density of 0.55t/m³. | |||||