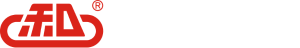

Performance Characteristics

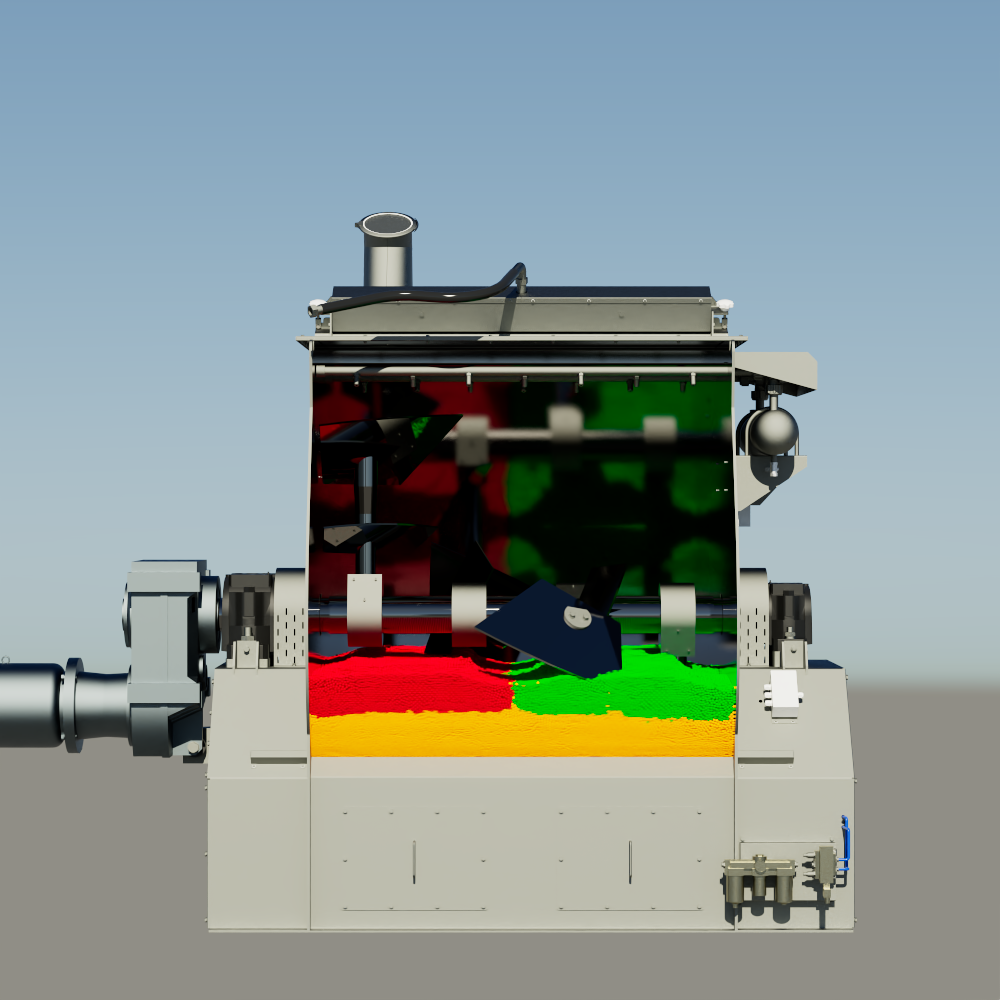

- 1. Inner and outer double-layer blade design, special arrangement structure, high mixing uniformity, short mixing cycle; Mixing time 1-3 min, coefficient of variation CV≤5%; Materials with large physical property differences such as specific gravity, particle size and shape are not easy to produce segregation when mixing.

- 2. Equipped with liquid adding system, can add a variety of liquids (water, grease, molasses, etc.).

- 3. The variable range of filling coefficient is large, from 25% to 100%.

- 4. Adopt hard tooth surface reducer and rotor direct transmission; Stable and reliable transmission, long service life, very low maintenance cost.

- 5. Adopt full-length large door discharging structure, fast discharging, ensure low residue, prevent cross contamination.

- 6. Equipped with safety interlock, protect personal safety.

- 7. Carbon steel or stainless steel can be selected according to different uses.

- 8. Suitable for feed additives, chemical, pharmaceutical, pesticide, dye and food industries.

- 9. Technical description, product model, power, effective volume, batch mixing amount, mixing time, coefficient of variation.

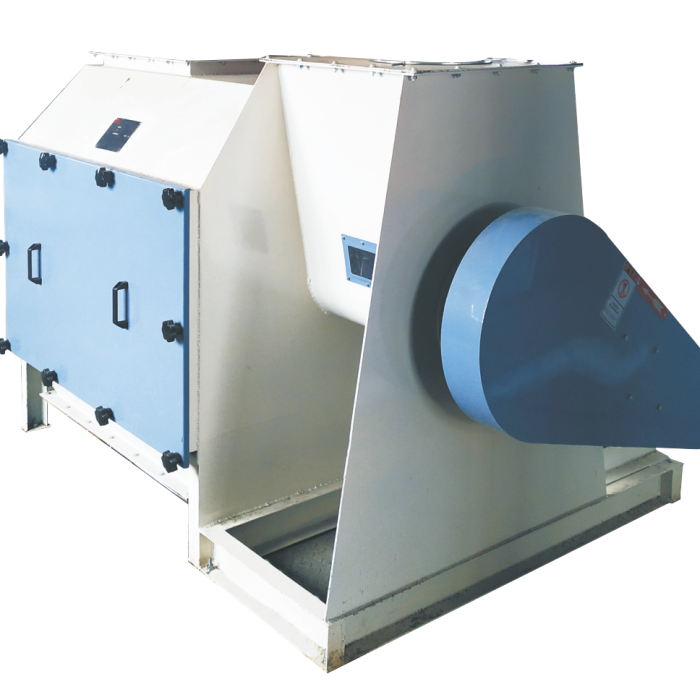

Performance Characteristics

The host pipes and wiring are integrated into integrated channels to facilitate daily maintenance and inspection;

Equipped with multiple liquid adding points, a variety of liquids (water, grease, molasses, etc.) can be added for easy cleaning

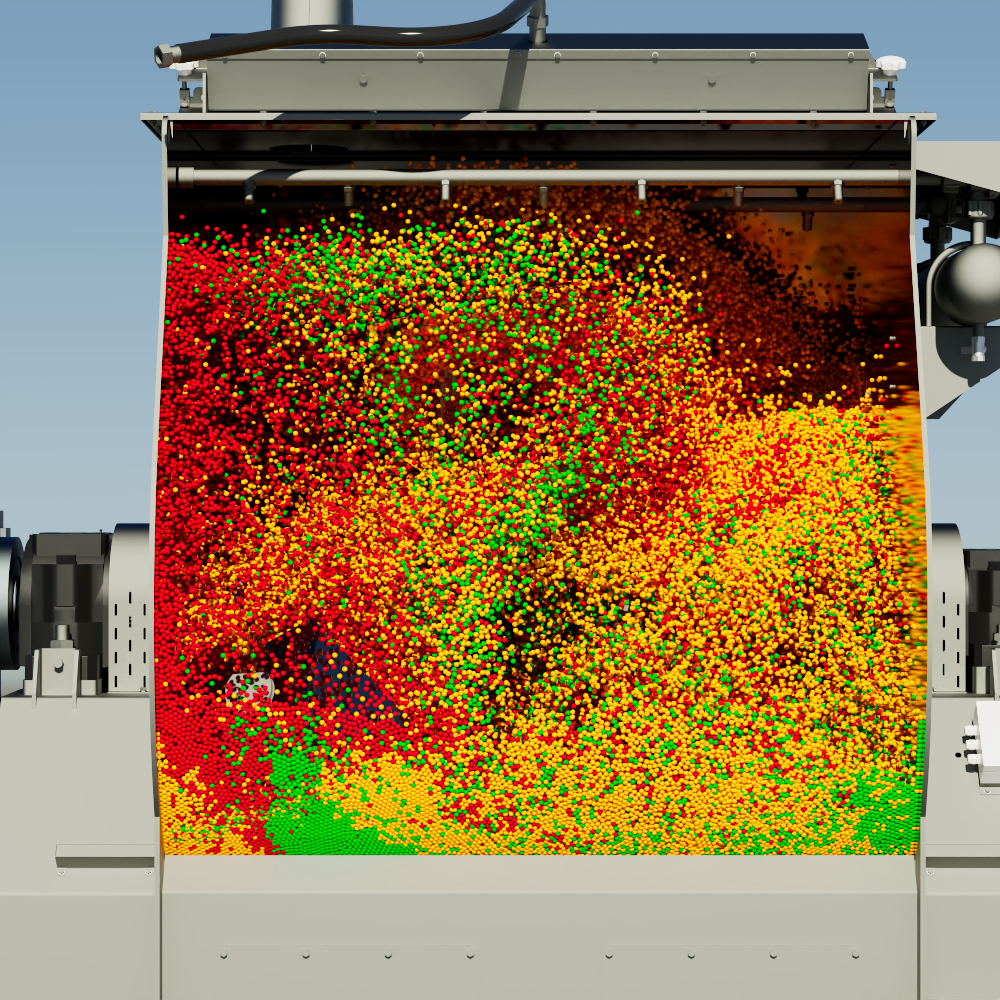

Hexie single-shaft paddle mixer mixes at high speed and efficiently; it can complete mixing of a batch of materials in about 90 seconds;

The spindle is equipped with a reverse rotation counting start and stop device to meet automatic cleaning:

The bottom adopts the form of a full-length open door for rapid discharge:

Equipped with assembled adjustable paddles for easy cleaning and maintenance:

The whole machine is highly efficient and energy-saving, and the energy-saving rate is 1/3 of traditional mixers:

The mixing uniformity is as high as over 97%, CV≤5%:

Carbon steel or stainless steel materials can be customized according to different uses.

Technical Description

| Product Model | Power(kw) | Effective Volume (m³) | Capacity(kg/batch) | Mixing Time(min) | Coefficient of Variation (cv) |

| HHDJ-0.5 | 5.5 | 0.5 | 250 | 1-3 | ≤5% |

| HHDJ-1.0 | 15 | 1.0 | 500 | ||

| HHDJ-2.0 | 22 | 2.0 | 1000 | ||

| HHDJ-4.0 | 37 | 4.0 | 2000 | ||

| HHDJ-6.0 | 45/55 | 6.0 | 3000 | ||

| HHDJ-8.0 | 2×37 | 8.0 | 4000 | ||

| HHDJ-10.0 | 2×45 | 10.0 | 5000 |